Description

Chemical Tanker Trailer Transport Corrosive Liquid

Chemical Tanker Trailer Triple-Layer Protection. Stainless steel (SS316L/2205) inner shell resists acids, alkalis, and solvents. Outer carbon steel frame includes anti-UV epoxy coating.

Smart Compartmentalization. 3–7 modular compartments (2,000–40,000L total capacity). Prevent cross-contamination with laser-welded baffles.

Easy Cleaning. FDA-approved smooth inner surface (Ra ≤0.8μm). Reduces residue by 90% vs. standard tanks.

Technical Specifications

Capacity: 20,000–45,000 liters

Working Pressure: 0.3–4 bar (customizable)

Wall Thickness: 5–12mm (material-dependent)

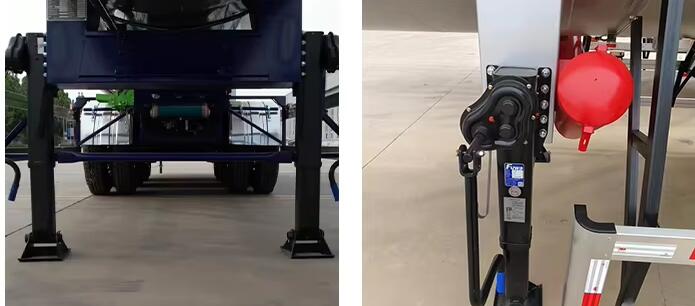

Axles: BPW/FUWA/ZW 13-ton axles, air disc brakes

Certification: ADR 2023, ASME, ISO 1496-3

Competitive Advantages

Unlike generic tankers, our Dual Safety Seal System combines robotic weld seams and vulcanized gaskets. Achieves zero leakage at ±50°C temperature swings.

Additionally, the V-shaped chassis design improves stability on sharp turns. Minimizes liquid surge by 40% compared to flat-bottom tanks. Optional heating/cooling jackets maintain -20°C to +150°C temperatures.

Cost-Saving Benefits

- 30% Faster Loading/Unloading: Top-mounted 10-inch manholes + bottom discharge valves.

- Reduced Downtime: Interchangeable components (valves, pumps) cut repair time by 50%.

- Global Compliance: Meets IMDG, EPA, and REACH regulations.

Target Industries

- Chemicals: Transport sulfuric acid, methanol, or adhesives safely.

- Food & Pharma: Sanitary design supports edible oils, syrups, and vaccines.

- Energy: Ideal for liquid asphalt or LNG additives.

Contact us today for a detailed quotation. ZW GROUP Chemical Tankers: Safety Engineered. Performance Guaranteed.

.png)

Reviews

There are no reviews yet.